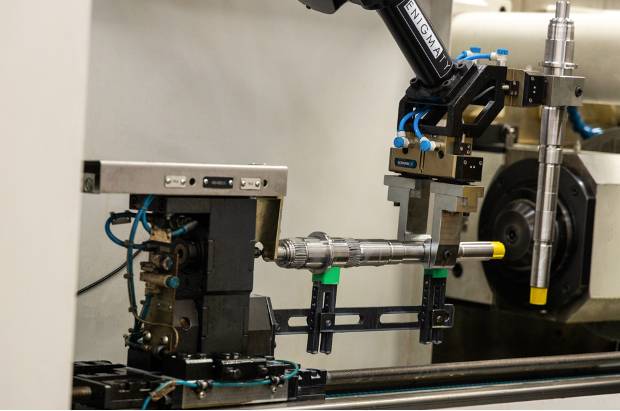

CNC & GEAR SHOP

Echjay’s CNC and Gear Shop produces over 600,000 machined components every month.

The shop is equipped with:

- CNC turning machines

- Spline Rolling Machines

- Hobbing Machines

- Internal Grinding Machines

- Broaching Machines

- Honing Machines

- Shaving Machines

- Shaping Machines

- Cylindrical Grinding Machines

- Vertical machining centers

- Horizontal lathe machines for manufacturing flanges and general engineering products

- Gear tooth rounding, roofing and chamfering machines

- Carburizing furnaces for heat treatment of gears

CROWN WHEEL & PINION GEAR CUTTING

| Sr. No. | Manufacturing Facility | Characteristic |

|---|---|---|

| 1 | Blade Grinding & Cutter Assembly | • Klingelnberg B-24 & CS-200 |

| 2 | Gear cutting | • Klingelnberg C-50/C-40/C-29 & Gleason HC-450 |

| 3 | Heat treatment | • State of the art twin-track electric CGC Furnace |

| 4 | Post Heat treatment |

• CNC Hard Turning • CNC Pinion OD and ID Grinding |

| 5 | Lapping/Testing | • Klingelnberg L-50/ T-50 & T-60 with MTE |

| 6 | Quality | • Klingelnberg P-65 |