Qualified Team of QC Engineers

Our material testing laboratories are operated by team of trained and qualified Quality Control Engineers who ensure accurate,compliance with specified quality standard,and reliable product acceptance prior to shipment.

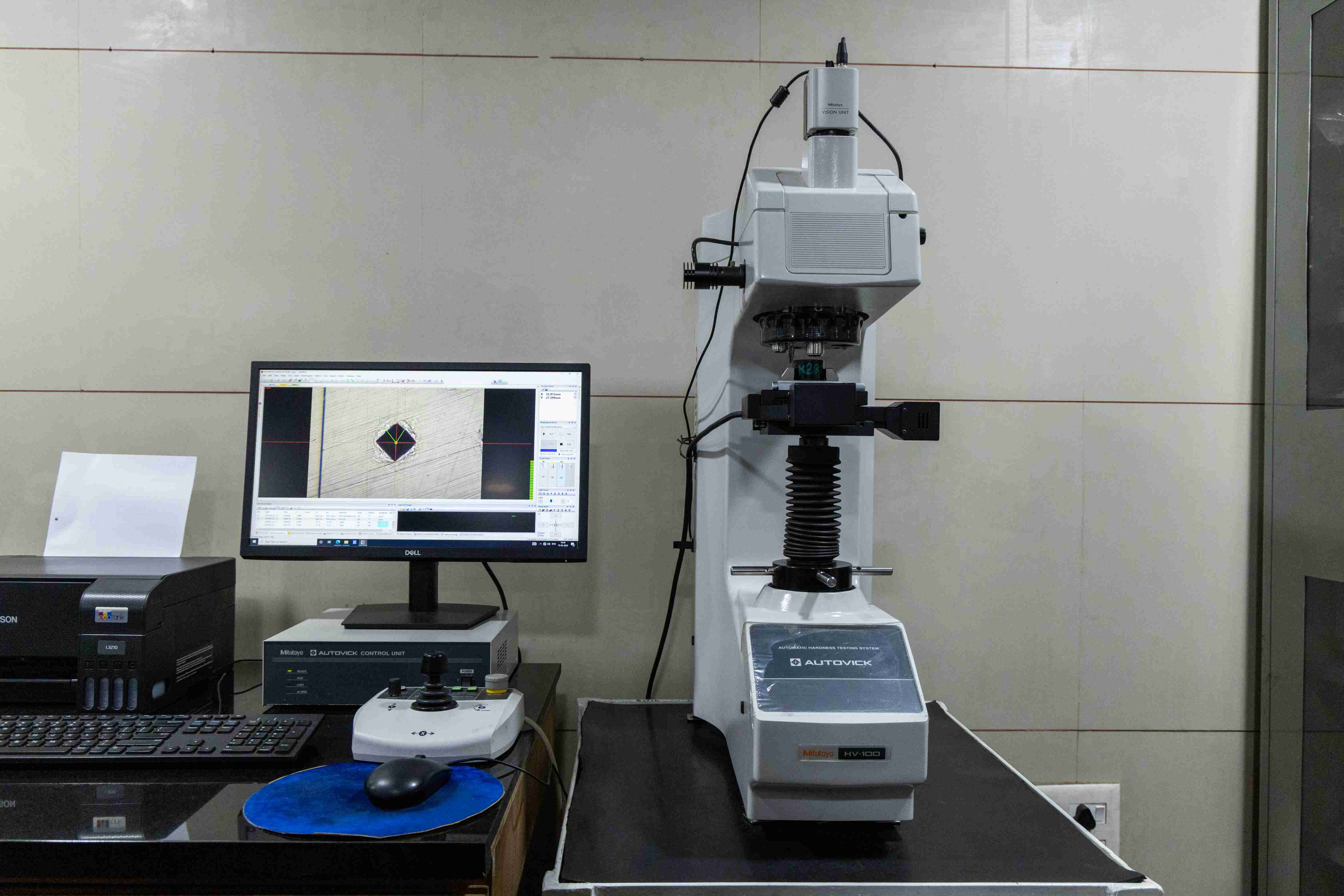

Standard Room and In-House Metrology Calibrations

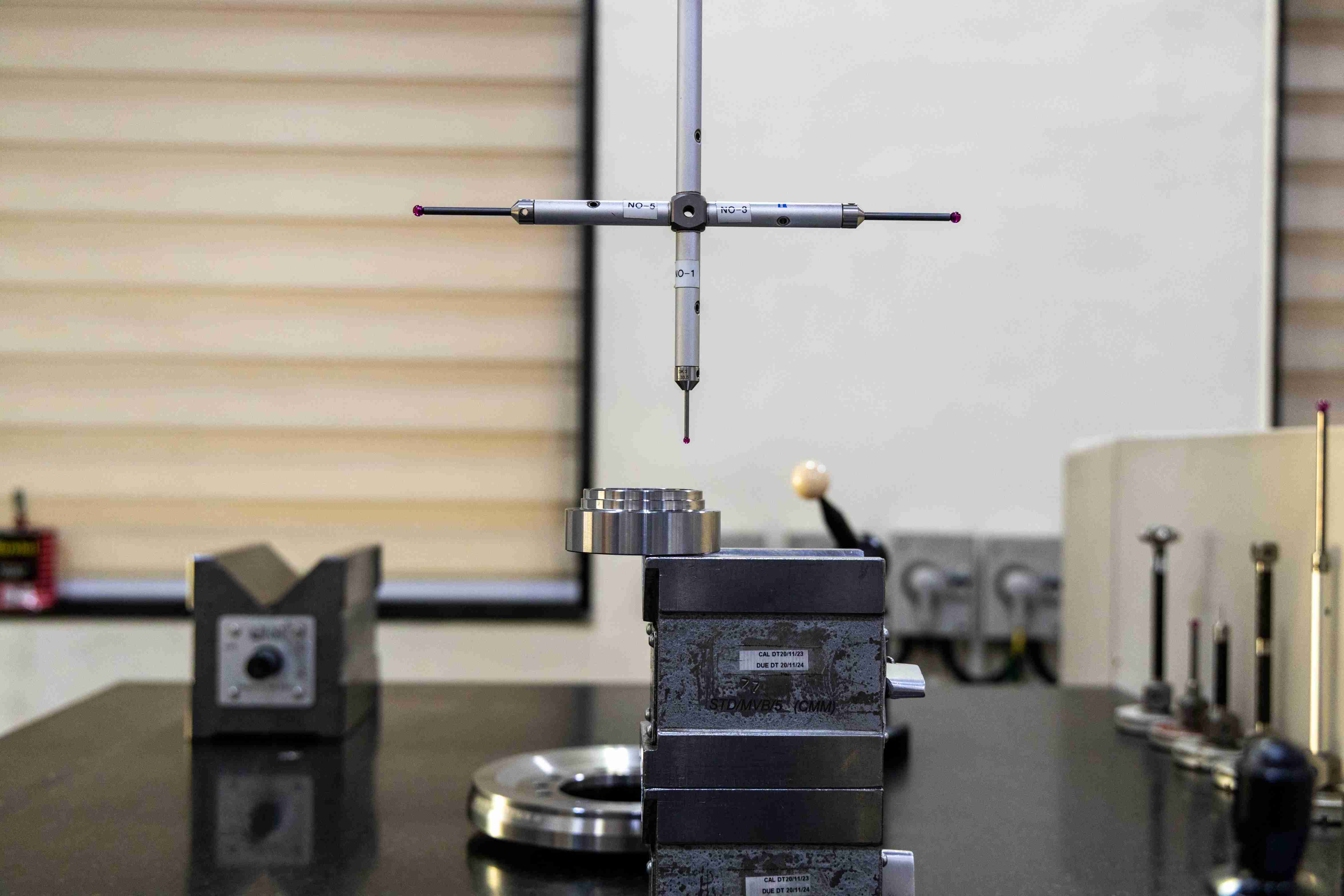

A fully equipped standard room with precision inspection equipment for in-house calibration of all dimensional measurement instruments, gauges, jigs, and fixtures, traceable to the Government National Physical Laboratory.

Additional test equipment includes Gear Lead & Profile Testing Machine, Gear Pitch Testing Machine, Profile Projector, 2D Digital Height Gauge, and Portable CMM.

Additional test equipment includes Gear Lead & Profile Testing Machine, Gear Pitch Testing Machine, Profile Projector, 2D Digital Height Gauge, and Portable CMM.

Chemical / Spectrometry Lab

-

Wet Analysis,Emission Spectrography,X-Ray Metal Grade testing

Non-Destructive Testing

Equipped with Ultrasonic Flow Detector, Dye Penetrant Test, Magnetic Particle Testing and Eddy Current Testing. QC Engineers are qualified as per ASNT Standards.

Computer-aided SQC Systems for Product Quality and Process Control

The system includes a fully automatic CNC gear measuring machine, Wenzel WGT 350 and P40 Klingelnberg capable of measuring workpieces up to 400mm diameter and 700mm between centers, with hob and shaving cutter software. Additionally, an online electronic measuring system ensures process control on CNC turning centers, with post-process control and automatic tool wear compensation.